-

- Languages

- Bahasa

- Rudolf Worldwide

- RUDOLF Germany

- HUB 1922

- RUDOLF Italy

- RUDOLF Indonesia

Why do the feathers of birds not become wet? Why does this type of water repellency in nature work without perfluorinated compounds?

The RUDOLF GROUP has answered these questions by means of the scientific branch Bionic. Bionic does not mean to just imitate nature, but to realise its functional principles and to transfer them to technical solutions. Thus, novel, sustainable and ecologically advantageous technologies for imparting hydrophobic properties have been developed.

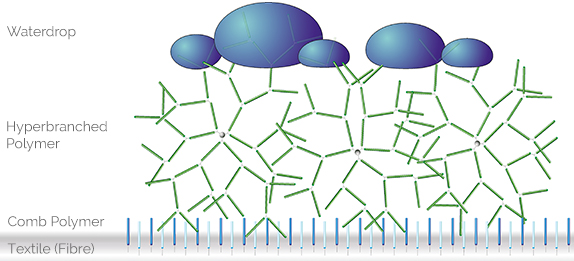

Hydrophobic finishing with BIONIC-FINISH® ECO is based on a fluorine-free recipe. Hyperbranched, hydrophobic polymers with ramified structures like in tree tops orientate in an orderly manner on the textile and crystallise on specifically adusted comb polymers. The optimum arrangement of many of these functional elements is highly effective. Additional boosters (crosslinking agents) ensure the optimum attachment and durability on many fibre substrates.

By means of Bionic RUDOLF develops novel, sustainable and ecologically advantageous technologies in the field of hydrophobic finishing. BIONIC-FINISH® ECO combines ecology and trend-setting hydrophobic finishing of textiles.

Hyperbranched polymers can be produced step by step by combining multifunctional components. With each synthetic step of these hyperbranched polymers the number of reactive end groups grows exponentially.

The specific control of reactions enables to functionalise end groups with hydrophobic residues at the end of a series of synthetic steps, which results in an extreme density of water-repellent groups. These hyperbranched, hydrophobic polymers are highly effective and, due to their network structure, tend to self-organise and crystallise.

For optimum orientation and attaching to the fibre surface, ®RUCO-DRY ECO and ®RUCO-DRY ECO PLUS, the finishing products of BIONIC-FINISH®ECO, does not only use hyperbranched polymers but also specifically adjusted “comb“ polymers. The water-repellent effect level obtained by initial textile finishing has so far only been possible with fluorocarbon polymers.

Perfluorinated surfactants (PFTs) is the generic term for all fluoro-organic compounds with a surfactant character.

The best known representatives of this group are perfluorooctane sulfonic acid (PFOS) and perfluorooctanoic acid (PFOA). These substances are watched because they are not degraded in the environment and, as far as toxicity is concerned, have not been thoroughly examined yet.

In media discussions, water, oil and soil repellents based on fluorocarbons, by mistake, have often been named as a source of these substances. However, neither of them are used at all for impregnating textiles, but are found at most in smallest quantities as a byproduct when manufacturing fluorinated impregnating agents. The majority of PFTs reach nature by way of fire-extinguishing foams, galvanic processes or the semiconductor technology.

With the so-called C6 fluorine chemistry we have succeeded in developing PFOS and PFOA-free fluorocarbon water repellents. However, many manufacturers of brand name clothing would like to offer trend-setting fluorine-free textiles to their customers and, thus, sustainably reduce the impact on nature.

No perfluorinated compounds are used for manufacturing BIONIC-FINISH® ECO products. Such a finish avoids releasing PFOS and PFOA and opens up new perspectives to the clothing sector.

BIONIC-FINISH® ECO offers security to manufacturers - for protecting their labels and textiles.

BIONIC-FINISH®ECO offers a variety of consumer-friendly properties!

We are happy to assist you in implementing the process on your articles.